Nickel wire mesh is a versatile material renowned for its high corrosion resistance, heat stability, and excellent electrical conductivity. This wire mesh is manufactured from high-quality woven nickel wire. This wire mesh is widely used in chemical processing, electronics, aerospace, and water treatment industries. Its ability to withstand harsh environments and high temperatures makes it ideal for filtration, separation, and high-temperature applications. Nickel wire mesh is also utilized in medical devices and as a catalyst in chemical reactions, showcasing its broad applicability and essential role in various industrial processes.

Nickel wire mesh is woven using high-purity nickel wire, offering high strength, excellent corrosion resistance, and good thermal conductivity. These properties make it ideal for a variety of applications. This metal mesh is widely used in industries such as chemical processing, metallurgy, petroleum, electrical engineering, and construction, where durability and reliability are critical. Its versatility and robustness ensure its effectiveness in harsh environments and demanding applications.

Nickel wire mesh is highly popular as filtration media, nickel catalyst, and nickel mesh electrode due to its excellent properties. It boasts a high resistance to various chemicals, including caustic acids and alkalis, and its outstanding corrosion resistance makes it ideal for maintaining product purity in food production, synthetic fibres, and caustic alkalis. Additionally, nickel wire netting is utilized in corrosion-resistant parts, electronic components, aerospace applications, and more, underscoring its versatility and reliability in demanding environments.

Ambani Metals is India's leading manufacturer, supplier, and exporter of nickel wire mesh. Our wire mesh screens are ideal for filtration, separation, and various other industrial applications. Crafted with the highest quality nickel wire, our welded wire mesh exemplifies superior craftsmanship, ensuring customer satisfaction through reliability and performance.

Applications of Nickel Woven Wire Mesh :

- Off-Shore Oil Drilling

- Power Generation

- Petrochemical Industry

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Sea Water Equipment

- Heat Exchangers & Condensers

- Pulp and Paper Industry

Nickel Welded wire mesh properties :

- Corrosion resistant

- Highly stable and resistant to alkalis.

- It shows good resistance and stability in acids, alkalines and neutral salt solutions.

- Shows good resistance to dry gases at room temperature and at higher temperature upto 1022 f

Specificationss of Nickel Wire Mesh :

- Wire Diameter : 0.05 mm to 8 mm

- Opening Size : 0.05mm to 30mm

- Mesh : 0.5 to 250 Mesh

- Mesh Wide : Upto 3000mm

- Grades : Nickel 200 Mesh, Nickel 201 Mesh

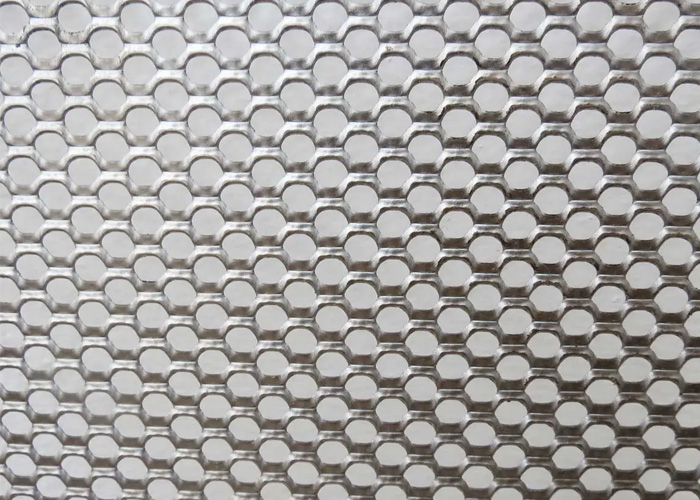

- Types : Woven Wire Mesh, Welded Wire Mesh, Expanded Metal Mesh, Perforated Metal Mesh, Knitted Wire Mesh, Hexagonal Wire Mesh,Crimped Wire Mesh