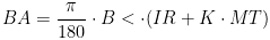

Bend Allowance (BA) – The amount of added to the sum of the two leg lengths to obtain the flat pattern length.

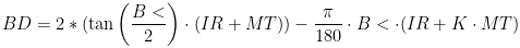

Bend Deduction (BD) – The amount removed from the sum of the two flange lengths to obtain a flat pattern.

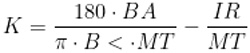

K-Factor (K) – The ratio of the position of the Neutral Axis to the Material Thickness.

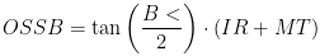

Outside Setback (OSSB) – Distance between the outside tangent points and the apex of the outside mold lines.

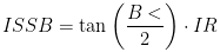

Inside Setback (ISSB) – Distance between the inside tangent points and the apex of the inside mold lines.

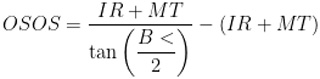

Outside Offset (OSOS) – The measurement from the surface of the outside radius to the apex of the outside mold lines. When calculating the outside offset use the included bend angle.

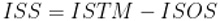

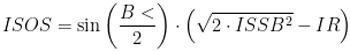

Inside Offset (ISOS) – Distance between the inside mold lines and the bend line.

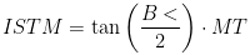

Inside Through the Material (ISTM) – The distance between the outside and inside mold lines.

Inside Shift (ISS) – Distance between the outside mold lines and the bend line.