Liquid-Liquid Extraction Process is a specialized separation process employed when simpler methods like distillation are insufficient to meet specific requirements. In Liquid-Liquid Extraction process, components are extracted from a feed mixture using a solvent, without the need for an evaporation step. Liquid-Liquid Extraction Distributors are integral to this process, as they are used in extraction columns to manage both continuous and dispersed phases. These Liquid Liquid Extraction Distributors play a crucial role in preventing emulsions, especially at low surface tensions, ensuring efficient phase separation and improved extraction performance. This makes Liquid-Liquid Extraction a preferred choice in industries where precise separation is essential.

FAQs

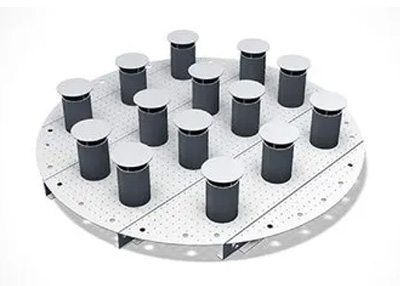

A Liquid-Liquid Extraction Distributor is a device used in the process of liquid-liquid extraction to evenly distribute the feed mixture (comprising of two immiscible liquids) across the extraction column. This ensures optimal contact and mass transfer between the two phases, enhancing the efficiency of the extraction process.

The distributor functions by evenly distributing the incoming liquid feed into fine droplets or streams. This is typically achieved through various designs like perforated plates, packed beds, or rotating disks. The key goal is to maximize the surface area for contact between the two immiscible liquids, which facilitates efficient mass transfer of solutes from one phase to the other.

Uniform distribution is crucial because it ensures that the two liquid phases have maximum contact area, leading to more effective mass transfer. Non-uniform distribution can result in poor extraction efficiency, as some parts of the column may have insufficient mixing, leading to inadequate separation of the desired compounds.