The demister pad is a cost-effective and versatile solution for separating and filtering gases and liquids, finding extensive use in industries such as chemical, pharmaceutical, petroleum, papermaking, and more. Ambani Metals offers a wide range of demister pads tailored to suit various equipment, applications, and environments.

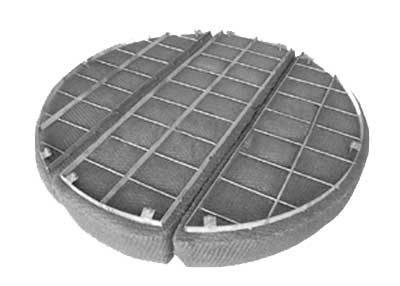

A demister pad, also known as a mist eliminator or demister, is a device used to remove liquid droplets or mist from a gas stream. It typically consists of a mesh-like structure made of materials such as metal, plastic, or fiberglass. This mesh intercepts and captures liquid droplets present in the gas stream, allowing the gas to pass through relatively unhindered. Demister pads are commonly used in various industrial processes such as chemical processing, oil refining, power generation, and air pollution control. They play a critical role in ensuring the quality of gas streams, preventing corrosion in downstream equipment, and meeting environmental regulations by removing harmful pollutants.

Features

- Efficient Mist Removal: Demister pads effectively capture liquid droplets or mist from gas streams, ensuring the gas exits with reduced moisture content. This helps maintain the quality of the gas and prevents potential damage or corrosion in downstream equipment.

- Improved Equipment Performance: By removing moisture or liquid particles from gas streams, demister pads help prevent fouling and corrosion in equipment such as compressors, heat exchangers, and pipelines. This can extend the lifespan of equipment and reduce maintenance costs.

- Enhanced Process Efficiency: Cleaner gas streams resulting from demister pad usage can improve the efficiency of various industrial processes, such as chemical reactions, refining operations, and power generation.

- Environmental Compliance: Demister pads aid in meeting environmental regulations by removing pollutants and harmful substances from gas streams before discharge into the atmosphere. This contributes to cleaner air and helps industries comply with emission standards.

- Versatility: Demister pads are available in various materials, configurations, and sizes, making them adaptable to different operating conditions and applications across a wide range of industries.

Applications

- Separating Liquid Droplets: Demister pads help to remove liquid droplets entrained in vapor streams during the distillation process. This is particularly important in fractional distillation, where the goal is to separate different components of a liquid mixture based on their boiling points. By removing liquid droplets, demister pads enhance the purity of the vapor phase and improve the separation efficiency of the distillation column.

- Preventing Tray Fouling: In trayed distillation columns, demister pads are often installed above the trays to prevent liquid carryover from one tray to another. Liquid carryover can lead to tray fouling and reduced column efficiency. Demister pads intercept liquid droplets and prevent them from reaching the trays below, thus maintaining optimal tray performance and improving overall column efficiency.

- Protecting Equipment: Demister pads also help protect downstream equipment, such as reboilers and condensers, by removing liquid droplets from vapor streams before they enter these units. Preventing liquid carryover into reboilers and condensers helps to maintain their thermal efficiency and prolongs their operational life.

- Maintaining Product Purity: In distillation processes where product purity is critical, such as in the production of high-purity chemicals or fuels, demister pads ensure that the vapor phase leaving the distillation column is free from liquid contaminants. This helps to meet product specifications and quality requirements.

FAQs

A demister pad, also known as a mist eliminator or mist pad, is a specialized device used to separate liquid droplets from gas streams. It consists of a mesh-like structure designed to capture and coalesce liquid droplets, allowing them to drain back into the process stream.

Demister pads operate on the principle of inertia and impingement. As gas containing liquid droplets passes through the pad, the droplets collide with the pad's fibers or surfaces. This causes them to coalesce into larger droplets, which then fall back into the liquid phase due to gravity, while the gas continues on its path.

The demister pad finds extensive application across various industries, including chemical, petroleum, pharmaceutical, light industry, and metallurgy. It serves as a crucial vapor-liquid separation device in vertical cylindrical equipment. Moreover, it proves beneficial in desulfurization processes and other production activities by effectively eliminating oil mist as well as toxic and poisonous gases.

Demister pads provide multiple benefits in industrial applications. They efficiently separate liquid droplets from gas streams, ensuring product purity. Moreover, they aid in environmental compliance by reducing liquid pollutant emissions. Additionally, demister pads safeguard equipment from damage by preventing liquid entrainment, reducing maintenance costs and downtime. They also contribute to energy savings by minimizing the loss of valuable liquids, thereby optimizing process efficiency. Overall, demister pads enhance product quality, environmental responsibility, equipment protection, and energy efficiency across diverse industrial processes.