Leading Brass Wire Mesh Manufacturer in India

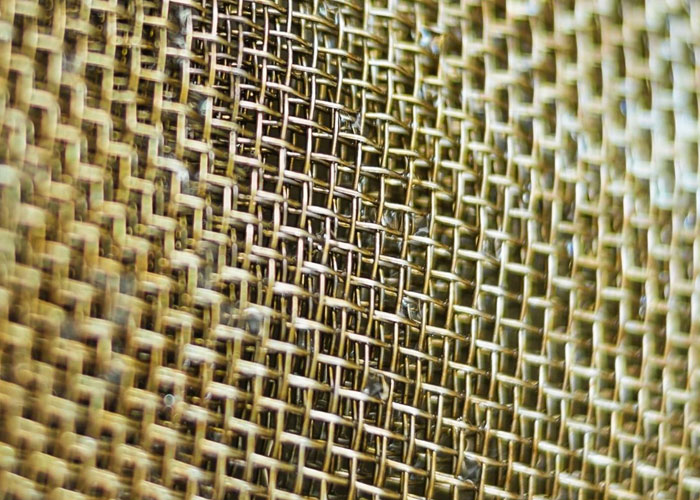

Ambani Metals is a premier brass wire mesh manufacturer based in Mumbai, India. We have established ourselves as a key player in the brass wire mesh industry within India. With extensive business experience and expertise, Ambani Metals has positioned itself as a top-tier producer and supplier in the global brass wire mesh market. We supply significant quantities of brass wire mesh, including various types of brass mesh screens and brass mesh sheets, to meet diverse client needs. Our commitment to high-quality manufacturing has earned us recognition as one of India's leading brass wire mesh manufacturers.

Our copper wire mesh is a customized product, made precisely to customer specifications. We ensure thorough documentation at every production stage to maintain accurate records of all customized products. The finished goods undergo rigorous quality control checks before leaving our premises to guarantee top-notch quality.

Understanding Brass Wire Mesh

Brass wire mesh is an alloy of copper and zinc, offering better resistance to abrasion and corrosion compared to pure copper. While it has lower electrical conductivity than copper, brass is frequently used in applications requiring durability, such as sieving diverse pellets, powders, porcelain clay, and glass, as well as filtering liquids and gases.

Crafted from brass wire, phosphor bronze wire, or copper wire, our brass mesh screens are ideal for separation and sifting processes across industries like mining, petroleum, chemicals, electronics, and transport. The chemical composition of brass typically contains 60-70% copper and 30-40% zinc, making it superior to copper wire mesh in terms of abrasion resistance and tensile strength.

Versatile Applications of Brass Wire Mesh

Brass mesh is fairly stiff but can be bent by hand and easily cut with tin snips or scissors. Its superior abrasion resistance and tensile strength make it a preferred choice in various industrial applications. Brass is especially valued for projects that require strength without electrical conductivity, showcasing a distinctive golden-yellow hue that makes it highly attractive for DIY, decorative, and artistic purposes.

At Ambani Metals, we maintain a comprehensive inventory of high-quality brass mesh sheets and wire mesh products, ready for use in desired applications. Our dedicated fleet of weaving machines is continuously engaged in manufacturing premium quality brass wire mesh in both standard and customized weaving patterns. We pride ourselves on being specialists in brass wire mesh and other superior quality wire mesh products, ensuring we meet our customers' specific requirements and achieve complete satisfaction.

Properties of Brass wire mesh

- Excellent resistance to atmospheric corrosion, though susceptible to tarnishing.

- Lower than copper, making it suitable for applications that require reduced conductivity.

- Superior resistance to wear and tear compared to copper wire mesh.

- High tensile strength, allowing it to withstand significant stress.

- Can be woven into various mesh patterns and sizes to suit specific needs.

- Suitable for applications in filtration, sieving, and decorative purposes across various industries.

- Can be cut with common tools and shaped for custom applications.

Types of Copper Wire Mesh :

- Plain Weave Brass Wire Mesh

- Dutch Weave Brass Wire Mesh

- Twilled Weave Brass Wire Mesh

- Perforated Brass Sheets

- Brass Mesh Screens

- Expanded Brass Mesh

- Brass Wire Cloth

Applications of Brass wire mesh

- Used in liquid and gas filtration for industries like chemical processing, petroleum, and water treatment.

- Ideal for sifting and sorting materials such as powders, grains, and pellets in mining and agriculture.

- Popular for architectural applications, DIY projects, and artistic designs due to its attractive golden-yellow hue.

- Used in windows and doors for durable insect screens that also provide corrosion resistance.

- Applied in automotive and industrial settings for heat shielding due to its thermal resistance.

- Brass wire mesh screens are used to shield electronic devices from electromagnetic interference.

- Suitable for creating sculptures, jewelry, and other artistic items because of its malleability and appealing look.

- Employed in sound insulation products to reduce noise and vibration.

- Used in plaster reinforcement, concrete flooring, and wall structures for added durability.

- Utilized for strainers, filters, and protective covers due to its resistance to saltwater corrosion.

FAQs

Brass wire mesh is composed of an alloy consisting of 60-70% copper and 30-40% zinc. This combination gives it better abrasion resistance and tensile strength compared to pure copper.

Brass wire mesh is used for filtration, sieving, insect screens, decorative purposes, EMI shielding, heat shielding, crafting, sound insulation, and reinforcement in construction.

Yes, brass wire mesh has good resistance to corrosion, especially in atmospheric conditions. However, it may tarnish when exposed to ammonia or certain salts.

Brass wire mesh is available in various mesh sizes, ranging from fine mesh (with small openings) to coarse mesh (with larger openings), suitable for different filtration and separation needs.

Yes, brass wire mesh is relatively easy to cut and shape using tin snips or scissors. It can be bent by hand, making it suitable for DIY projects and custom applications.

Industries such as chemical processing, construction, mining, agriculture, marine, electronics, and the arts commonly use brass wire mesh for various applications.