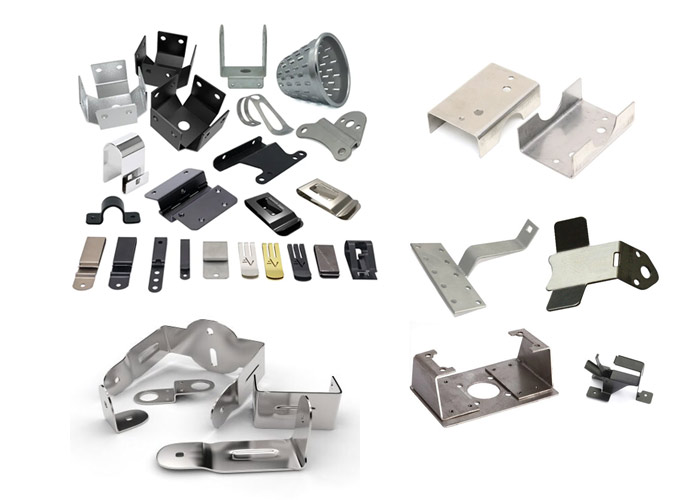

Metal Part Stamping for Electronics Industry

Ambani Metals stands as a leading Electronic Components manufacturer with a strong focus on electronics metal stamping. Utilizing state-of-the-art metal stamping equipment and streamlined processes, we deliver highly precise, custom electronic stamping solutions that cater to the specialized demands of the electronics industry. Our reputation as a top-tier Electronic Components manufacturer is built on the production of superior components, achieved through high-end progressive-die metal stamping machinery and rigorous quality control measures throughout every stage of production.

In the dynamic electronics sector, where precision, detail, and uniformity of parts are crucial, excelling in electronics metal stamping is essential for success. Our advanced stamping techniques facilitate the rapid, precise, and consistent manufacturing of even the smallest components, ensuring high quality and reliability, even in extensive production runs.

Materials : Stainless Steel, Aluminum, Steel, Brass, Copper, Titanium, Platinum, Inconel, Hastelloy, Carbon Steel

The Benefits of Metal Part Stamping in Electronics Industry

Cost-Effectiveness : Metal stamping provides a cost-effective approach by accommodating long production runs with short turnaround times, allowing us to produce large volumes of identical components. This scalability helps companies efficiently grow their operations while offsetting the upfront costs of tooling and setup, making it an ideal choice for the dynamic electronics industry.

Customization : Customization is at the core of our approach, enabling us to adapt designs, materials, and production methods to fit the specific needs of our clients. Whether it's intricate shapes, complex geometries, or specific material requirements, our metal stamping capabilities provide the versatility needed to produce components that precisely align with your project requirements, ensuring functionality and performance in every production run.

Material Efficiency : Material efficiency is a key advantage of our metal stamping process, allowing for maximum utilization of raw materials and reducing scrap. This not only lowers production costs but also supports sustainable manufacturing practices. By optimizing material usage, we deliver reliable, cost-effective solutions that meet the high demands of the electronics sector, ensuring that every component is produced with the utmost precision and efficiency.

Quality Consistency : Metal stamping is renowned for its high accuracy and consistency, achieving tolerances as tight as ± 0.0005 inches, depending on design and material selection. To maintain product consistency and quality, we employ rigorous quality assurance methods, such as optical monitoring, throughout the stamping process. Additionally, the high level of automation in metal stamping minimizes the potential for human error, ensuring the delivery of reliable components that meet the exacting standards of the electronics industry.

Stamped Components for Electronics Applications :

- Wearable fitness trackers

- Video doorbells

- Smart locks

- Heating and cooling devices

- Wireless speakers

- Televisions and monitors

- Smartphones

- Smart plugs

- Robotic vacuums

- Power strips

- Printers

- Lighting devices

- Kitchen appliances

- Heating and cooling systems

- Heads-up displays

- Fitness trackers

- Sensors

- Computer electronics

- Microphones

- Smart security systems

- Smart plugs and power strips

- Cameras