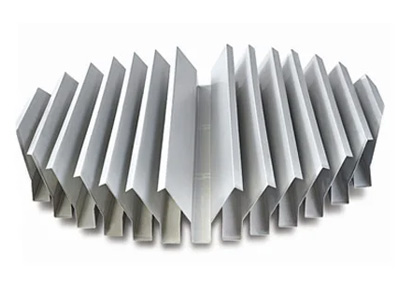

A vane collector tray is essential in towers handling high vapor loads and low liquid loads, streamlining the process by directly feeding liquid to the annulus for thorough mixing. Notably, this tray boasts minimal pressure drop and offers open areas ranging from 40% to 75%. It effectively mitigates entrainment, even under high vapor rates, a common challenge with traditional gas risers. Widely adopted across industries such as chemical, petroleum, pharmaceutical, metallurgy, and automotive, vane collector trays play a crucial role in optimizing operational efficiency.

Global Export of Vane Type Collectors

Ambani Metals is a trusted global manufacturer and exporter of vane type collectors, designed for efficient vapor-liquid separation and liquid collection in packed column systems. These collectors play a critical role in ensuring clean vapor disengagement while directing liquid accurately to downstream internals or draw-off points.

Our vane collectors are fabricated using high-performance materials such as Stainless Steel 304, 316L, Duplex Steel, Hastelloy, and Inconel, and are engineered to provide low pressure drop, high mechanical strength, and superior mist elimination—making them ideal for high-capacity, high-purity processing units.

Ambani Metals exports vane type collectors to customers in over 40 countries, serving diverse industries including refining, chemical, pharmaceutical, water treatment, and clean energy. We deliver components with full QA/QC compliance, export documentation, and world-class packaging.

- Middle East: Bahrain, Egypt, Israel, Jordan, Kuwait, Lebanon, Oman, Qatar, Saudi Arabia, and the United Arab Emirates

- Africa: Morocco, Tunisia, Ghana, Nigeria, Senegal, Kenya, Mauritius, Rwanda, Tanzania, Uganda, Zambia, Botswana, Eswatini, Lesotho, Namibia, and South Africa

- Europe: Germany, United Kingdom, France, Italy, Netherlands, Spain, Belgium, Poland, Czech Republic, Sweden, Denmark, Finland, Portugal, Hungary, Slovakia, Slovenia, Romania, and Austria

- Asia: Japan, South Korea, Singapore, Malaysia, Vietnam, Indonesia, Thailand, Philippines, Bangladesh, Sri Lanka, and Nepal

- Pan-Pacific Countries: United States, Canada, Mexico, Brazil, Chile, Colombia, Peru, Panama, Australia, and New Zealand

Why Choose Ambani Metals?

- Custom-engineered vane spacing, angle, and blade profile

- Modular design for ease of installation and maintenance

- Built for high capacity and severe duty operation

- Export-ready with full traceability and technical documentation

When vapor purity and efficient disengagement are critical, Ambani Metals' vane type collectors offer a high-performance solution tailored for your column. Whether you're designing a new unit or upgrading an existing system, we supply precision-engineered internals with global reach.

FAQs

A Vane Type Collector is a device used to improve the separation efficiency within process columns, such as distillation or absorption columns. It typically serves to coalesce and separate liquid droplets from vapor streams.

In a process column, a Vane Type Collector directs the vapor stream through a series of angled vanes. The design forces the vapor to change direction multiple times, which causes liquid droplets to coalesce and separate from the vapor due to inertia and gravitational forces. The collected liquid then drains down the column.

Enhancing the separation of components by removing entrained liquids from vapor streams.

- Increased Efficiency: Improved separation of liquid and vapor phases, leading to higher purity of the final products.

- Reduced Entrapment: Minimizes liquid carryover, which can negatively impact downstream equipment and processes.

- Lower Pressure Drop: Generally offers a lower pressure drop compared to other separation devices like mesh pads.

- Compact Design: Can be integrated into existing column internals with minimal modifications.

Vane Type Collectors are usually made from corrosion-resistant materials such as stainless steel, Hastelloy, or other alloys suitable for the process conditions. The choice of material depends on factors like chemical compatibility, temperature, and pressure within the column.